Custom Plastics Fabrication

At Johndec Engineering Plastics WA, plastic fabrication is more than a manufacturing process. It is a critical part of how we help businesses operate safely, reliably and in compliance with Australian standards. Based in Perth, we support the plastic fabrication industry across Western Australia with custom plastic manufacturing solutions designed for demanding industrial, laboratory, mining and commercial environments.

We work closely with engineers, contractors and facilities teams to deliver custom plastic fabrications that meet exact specifications, perform over time and support long-term safety outcomes. Every job is approached with care, technical expertise and a clear understanding of how plastics behave in real operating conditions.

Custom Plastic Manufacturing Built Around Performance and Safety

Our custom plastic manufacturing services are designed to support business needs where durability, precision and compliance matter. From early design through to fabrication and delivery, our highly skilled team manages the full process in-house, ensuring quality workmanship at every stage.

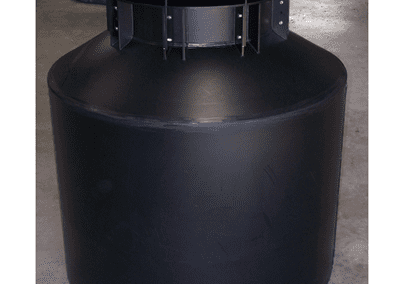

We manufacture plastic components to exact specifications, considering shape, thicknesses, material selection and how each product will operate in its final environment. Whether the project involves tanks, ducting components, guards or custom enclosures, our focus remains on quality products that perform reliably throughout their service life.

Supporting Industry Across Western Australia

We operate from our Perth location and proudly support clients throughout Western Australia. Our customers work across mining, industrial processing, laboratories, water treatment, caravans, commercial facilities and specialised manufacturing environments.

This breadth of experience allows us to match materials, fabrication techniques and production methods to the realities of each industry. We understand that plastics are often part of a larger system, and that failure is not an option where safety, durability and continuity of operations are involved.

A Large Range of Plastics and Fabrication Techniques

Johndec Engineering Plastics WA offers a large range of plastics and fabrication services to suit diverse project requirements. Our materials range includes polycarbonate for impact resistance and clarity, polyethylene for chemical resistance and durability, and PVC for ducting, containment and industrial applications, alongside other engineered plastics selected to suit operating conditions.

We work with multiple thicknesses and material grades to ensure the finished product matches its purpose. Our fabrication techniques include cutting, laser cutting, bending, forming, welding and precision assembly, all carried out within our Perth workshop. This combined capability allows us to control quality, cost and delivery while ensuring the fabrication process aligns with the technical and safety requirements of the job.

Plastic Fabrication Designed to Fit the Job

No two projects are the same. That is why our approach to plastic fabrication starts with understanding the application, not just the product. We take the time to ask the right questions, review drawings, assess loads, temperatures, chemicals and access requirements, and ensure the final design is fit for purpose.

From small one-off components to larger production runs, we provide plastic fabrication solutions that support operational needs today and into the future. Every product is designed to fit the space, match the system and operate as intended without compromise.

In-House Manufacture With Quality at the Core

All fabrication is carried out in-house by our experienced team. This allows us to maintain full control over the manufacturing process, from raw materials through to final inspection. Our commitment to quality means each job is produced with consistency, care and pride.

We do not treat plastic fabrication as a commodity. We treat it as an investment in safety, performance and longevity. By keeping manufacturing under one roof, we ensure that quality workmanship is not dependent on external suppliers or variable processes.

Expertise You Can Rely On

With decades of experience in plastics and engineered systems, Johndec Engineering Plastics WA brings practical expertise to every project. Our team understands how materials behave under stress, exposure and long-term use, and we apply that knowledge to design and fabrication decisions that matter.

We support clients across Australia who need dependable plastic fabrication for industrial and commercial applications, with a strong focus on Western Australia and Perth-based projects. Our solutions are built to deliver durability, reliability and peace of mind.

Balancing Quality, Cost and Long-Term Value

We understand that price and cost matter to every business. Our role is to help clients make informed decisions that balance upfront investment with long-term performance. We work transparently, providing guidance on materials, design options and fabrication methods that deliver value over time. Rather than chasing the lowest price, we focus on solutions that reduce maintenance, minimise risk and support future operation. This approach helps customers avoid costly rework and downtime, keeping systems working as intended.

Plastic Fabrication for Commercial and Industrial Applications

Our plastic fabrication services support a wide range of applications, including industrial tanks and water management components, guards and safety shields, laboratory and process plastics, mining and heavy industry components, and custom-fabricated parts for commercial facilities. Each product is manufactured to size, cut to suit, and finished to meet functional and safety requirements.

Custom Plastics Fabrication

Custom Equipment

- Polyvinyl Chloride (PVC)

- Polyvinylindenechloride (CPVC)

- Polypropylene (PP)

- Polyethylene (PE)

- Polyvinyl dene Fluoride (PVDF)

- Ethylene tetrafluoroethylene (ETFE)

- Ethylene – Chlorotrifluoroethylene

- Polymer (ECTFE)

- Polytetrafluoroethylene (PTFE)

- Fluorinated Ethylene propylene Polymer (FEP)

- Perfluoroalkoxy (PFA)

- Acrylics

- Acrylonitrile Butadiene Styrene (ABS)

Equipment that Johndec Engineering Plastics Pty Ltd have manufactured:

- Specialised fabrication and design.

- Custom made equipment.

- Fume cupboard and exhaust hoods.

- Exhaust fans and Fume Scrubbers.

- Lab sink bowls, drainers and troughs.

- Bench tops.

- Tanks and vessels.

- Launders.

- DIBK separation tanks.

- Electrowinning cells and spare parts.

- Corrosion proof machinery guards and shields.

- Corrosion protective liners.

- Supply of thermoplastics pipe, fittings and sheet.

- Pipe bending and slotting.

- Installation of thermoplastic pipe systems including bracketing and supports.

- Exhaust ducting.

- Chemical Neutralising Facilities.

- Plaster traps.

- Machining thermoplastics.

- On-site repairs and plastic welding.

A Team Committed to Getting It Right

At Johndec Engineering Plastics WA, our team takes pride in delivering plastic fabrication solutions that work. We bring experience, attention to detail and a commitment to doing the job properly, every time. From the first design discussion to final delivery, we work with clients as trusted partners.

If you are planning a project, upgrading an existing system or need expert advice on plastic fabrication, we are here to help. Bring your requirements, your challenges and your questions, and we will provide clear guidance and practical solutions that keep your business operating safely into the future.