In the world of electrical engineering, safety and efficiency are paramount. One material that stands out for its unique properties is non-conductive plastics. These materials are increasingly being used in various electrical insulation applications due to their ability to prevent electrical conductivity, protect sensitive components, and withstand harsh conditions. This article explores the benefits of non-conductive plastics, including their properties, applications, and the expertise of JohnDec Engineering in leveraging these materials effectively.

Key Takeaways

- Non-conductive plastics are essential for safe electrical insulation.

- They offer high dielectric strength, thermal stability, and resistance to chemicals.

- Common applications include switchboards, power equipment, and cabling solutions.

- Using non-conductive plastics can lead to cost savings and increased durability.

- JohnDec Engineering provides tailored solutions and high-quality materials for various projects.

Understanding Non-Conductive Plastics

Definition and Characteristics

So, what exactly are non-conductive plastics? Simply put, they’re plastics that don’t easily allow electricity to flow through them. This makes them super useful for electrical insulation. Think of it like this: metals are like open highways for electrons, while non-conductive plastics are like a road full of potholes – electrons just can’t get through easily.

The key characteristic is their high electrical resistivity. This means they resist the flow of electric current. Other important characteristics include:

- Low dielectric constant

- High dielectric strength

- Good thermal stability

Types of Non-Conductive Plastics

There’s a whole range of engineering plastics used in WA that fit the bill when it comes to non-conductivity. Some common examples include:

- Polyvinyl Chloride (PVC): Often used in wire and cable insulation due to its flexibility and low cost.

- Polyethylene (PE): Another common plastic, found in everything from shopping bags to cable jacketing. It offers good electrical insulation properties.

- Polypropylene (PP): Known for its chemical resistance and is often used in applications where exposure to harsh environments is a concern.

- Polyamide (Nylon): Offers a good balance of mechanical strength and electrical insulation, making it suitable for demanding applications.

- Fluoropolymers (e.g., PTFE or Teflon): These are the superheroes of non-conductive plastics, offering exceptional resistance to heat, chemicals, and electricity. They’re often used in high-performance applications.

Comparison with Conductive Materials

Okay, so why use non-conductive plastics instead of, say, metal? Well, there are a few key reasons. Metals are excellent conductors of electricity, which is great for wiring, but terrible if you want to prevent electrical shocks or short circuits. Plastics, on the other hand, offer excellent electrical insulation. Plus, they’re generally lighter, more resistant to corrosion, and easier to shape than metals. This makes them ideal for a wide range of non-metallic electrical components.

While metals excel in conductivity and structural strength, non-conductive plastics provide superior insulation, lighter weight, and resistance to corrosion, making them ideal for electrical applications where safety and durability are paramount.

Key Properties of Non-Conductive Plastics

Non-conductive plastics are pretty amazing materials, especially when you need to keep electricity where it should be. They’re not all the same, though. Different types have different strengths, so it’s important to know what you’re dealing with. Let’s look at some of the key things that make these plastics so useful in electrical applications.

Dielectric Strength

Dielectric strength is basically how well a material can resist electricity flowing through it. A high dielectric strength means the material can handle a lot of voltage before it breaks down and starts conducting. Think of it like a dam holding back water; the higher the dam, the more water it can hold. For electrical insulation, you want a material with a really high dielectric strength so it can safely contain the electricity.

- Different plastics have different dielectric strengths.

- Thickness affects dielectric strength; thicker materials generally resist higher voltages.

- Temperature and humidity can also impact a material’s dielectric strength.

Thermal Stability

Electrical components can get hot, so it’s important that the insulation doesn’t melt or degrade at high temperatures. Thermal stability refers to how well a plastic maintains its properties when it gets hot. Some plastics can handle high temperatures without any problems, while others will soften or even melt. You need to choose a plastic that can withstand the operating temperatures of your electrical equipment.

Choosing the right plastic with good thermal stability is important for safety and reliability. If the insulation fails due to heat, it could lead to short circuits, fires, or equipment failure.

Chemical Resistance

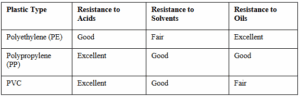

Electrical equipment is often exposed to all sorts of chemicals, like oils, solvents, and acids. You don’t want the insulation to break down when it comes into contact with these substances. Chemical resistance refers to how well a plastic can withstand exposure to different chemicals without degrading. Some plastics are highly resistant to a wide range of chemicals, while others are more vulnerable. It all depends on the specific plastic and the chemical in question.

Here’s a quick look at the chemical resistance of some common non-conductive plastics:

Applications in Electrical Insulation

Use in Switchboards

Switchboards are the central nervous system of any electrical distribution network, and electrical insulation materials are absolutely critical for their safe and reliable operation. Non-conductive plastics are increasingly becoming the go-to choice for switchboard components, replacing traditional materials like porcelain and bakelite. Why? Because they offer a superior combination of properties.

Think about it: the plastic casings, the internal supports, even the barriers that separate different voltage sections – all can be made from non-conductive plastics. This not only reduces the risk of short circuits and electrical shocks but also makes the switchboards lighter and easier to maintain. The use of plastics allows for more compact designs, which is a big win in space-constrained environments.

Integration in Power Equipment

Power equipment, such as transformers, generators, and motors, relies heavily on effective insulation to prevent breakdowns and ensure efficient performance. Non-conductive plastics play a vital role here, serving as insulating materials for electronics in various components. For example, you’ll find them used as coil formers, terminal blocks, and even as complete housings for smaller power supplies.

The high dielectric strength of these plastics means they can withstand high voltages without failing, which is obviously pretty important. Plus, their resistance to heat and chemicals ensures they can handle the harsh conditions often found in power equipment.

Cabling Solutions

Cables are the arteries of any electrical system, and their insulation is the first line of defence against electrical hazards. Non-conductive plastics are the dominant material for cable insulation, and for good reason. Polyvinyl chloride (PVC), polyethylene (PE), and cross-linked polyethylene (XLPE) are just a few examples of the plastic insulation solutions used to coat wires and cables of all sizes.

These plastics provide excellent electrical insulation, protecting people from shocks and preventing short circuits. They’re also flexible, durable, and resistant to abrasion, moisture, and chemicals, making them ideal for use in a wide range of environments.

From the tiny wires inside your phone charger to the massive cables that transmit power across the country, non-conductive plastics are keeping us safe and connected.

Advantages of Non-Conductive Plastics

Enhanced Safety

One of the most significant benefits of plastic insulators is the enhanced safety they provide in electrical applications. Non-conductive plastics prevent electrical shocks and short circuits, protecting both equipment and personnel. This is especially important in environments where accidental contact with electrical components is a risk.

Cost-Effectiveness

When you’re looking at the benefits of engineering plastics in electrical systems, cost is always a factor. Non-conductive plastics often present a more cost-effective solution compared to traditional materials like ceramics or specialised metals. The lower material cost, combined with easier manufacturing processes, can lead to significant savings.

For example, injection moulding allows for mass production of complex parts with minimal waste. The reduced weight of plastic components can also lead to lower transportation costs.

Durability and Longevity

Non-conductive plastics are known for their durability and longevity in various operating conditions. They are resistant to corrosion, chemicals, and extreme temperatures, ensuring a long service life. This is particularly important in harsh environments where other materials might degrade quickly.

The use of durable plastics reduces the need for frequent replacements and maintenance, saving time and money in the long run. Choosing the right type of plastic ensures that electrical components remain protected and functional for years to come.

JohnDec Engineering’s Expertise

Sourcing Quality Materials

At JohnDec Engineering, we understand that the foundation of any successful electrical insulation application lies in the quality of the materials used. That’s why we’ve established strong relationships with leading polymer manufacturers around the globe.

We meticulously select materials that meet stringent performance criteria, including dielectric strength, thermal and chemical resistance, and application-specific demands.

Custom Fabrication Services

We don’t just supply materials; we transform them. Our custom fabrication services are where your designs come to life. Whether you need intricate components for switchboards or robust housings for power equipment, we have the capabilities to deliver.

Using advanced techniques like CNC machining, injection moulding, and thermoforming, our team creates parts that meet your exact specifications. We collaborate with you at every stage—from concept to production—to ensure success.

Innovative Design Solutions

We believe that good design is about more than just aesthetics; it’s about solving problems. Our team of experienced engineers is dedicated to developing innovative solutions that push the boundaries of what’s possible with non-conductive plastics.

- Problem-focused approach: We start by understanding your specific challenges and then develop solutions that address them directly.

- Material expertise: We have a deep understanding of the properties of different non-conductive plastics and how they can be used to achieve optimal performance.

- Collaboration: We work closely with you throughout the design process to ensure the final product exceeds your expectations.

Future Trends in Non-Conductive Plastics

Emerging Technologies

The world of non-conductive plastics is constantly evolving, with new materials and processing techniques emerging all the time. Advanced polymer composites now offer even greater dielectric strength and thermal stability. Some even use nano-fillers or unique blends for enhanced performance.

Additive manufacturing (3D printing) is also making waves, allowing for more complex, customised parts with targeted material properties.

Sustainability Considerations

Sustainability is becoming a major driver in materials selection. There’s growing interest in bio-based and recyclable polymers to reduce environmental impact. The challenge is to maintain performance while meeting environmental goals, especially in power and electronic applications where safety is paramount.

Market Growth Projections

The market for non-conductive plastics is expected to grow steadily, driven by increasing demand across sectors like automotive, electronics, and renewable energy.

- Electrification of vehicles requires more insulation components.

- Renewable energy infrastructure needs high-performance insulation.

- Smaller, more efficient electronics require precise plastic engineering.

As innovation continues, non-conductive plastics will remain essential to modern electrical engineering—offering a blend of safety, performance, and sustainability for years to come.

Case Studies of Successful Implementations

Industry-Specific Examples

Let’s look at how non-conductive plastics are making a real difference across various industries. It’s not just about replacing metal; it’s about improving performance, safety, and lifespan. We’ll explore some specific cases where these materials have shone, answering the question of how non-conductive plastics are used in different industries.

Automotive

Non-conductive plastics are used extensively in electric vehicles (EVs) for battery housings and cable insulation. This reduces weight, increases range, and improves safety by preventing short circuits.

Medical

In medical devices, these plastics ensure patient safety by providing reliable insulation in sensitive equipment like defibrillators and diagnostic tools. They also offer chemical resistance to withstand sterilisation processes.

Renewable Energy

Solar panel junction boxes and wind turbine components benefit from the weather resistance and electrical insulation properties of these plastics, ensuring long-term reliability in harsh environments.

Performance Metrics

How do we measure the success of using non-conductive plastics? It comes down to a few key metrics. It’s not just about saying they’re good; it’s about proving it with numbers. Here’s a quick rundown:

- Dielectric Strength: Ability to withstand high voltage without failure.

- Thermal Stability: Resistance to heat degradation in operating environments.

- Chemical Resistance: Performance when exposed to industrial solvents and corrosive agents.

- Weight Reduction: Comparison with metal alternatives in lightweighting initiatives.

- Service Life: Years in operation without degradation or failure.

Wrapping Up the Benefits of Non-Conductive Plastics

In summary, using non-conductive plastics for electrical insulation is a smart choice for many applications. These materials offer impressive dielectric strength and heat resistance, making them suitable for everything from switchboards to power equipment and cabling.

JohnDec Engineering stands out in sourcing and fabricating these plastics, ensuring that you get the best quality for your projects. By opting for non-conductive plastics, you not only enhance safety but also improve the longevity and reliability of your electrical systems. It’s a straightforward decision that can lead to significant benefits in the long run.

Frequently Asked Questions

What are non-conductive plastics?

Non-conductive plastics are materials that do not conduct electricity. They are often used in electrical insulation to prevent electrical currents from passing through.

What are the main types of non-conductive plastics?

Common types include PVC, polyethylene, and polypropylene. Each type has different properties that make them suitable for various applications.

How do non-conductive plastics compare to conductive materials?

Unlike conductive materials, which allow electricity to flow, non-conductive plastics block electrical currents, making them safer for insulation.

What is dielectric strength?

Dielectric strength is a measure of how much electric field a material can withstand without breaking down. Higher values mean better insulation.

Where are non-conductive plastics used in electrical applications?

They are used in switchboards, power equipment, and cabling solutions to ensure safety and efficiency.

What are the benefits of using non-conductive plastics?

They enhance safety, are often cheaper than metals, and are durable, which means they last longer in electrical applications.