Plastic machining is a process that involves the shaping, cutting, drilling, and finishing of plastic materials to create specific parts or products. Over time, this process has undergone significant changes, driven by advancements in technology, materials science, and manufacturing practices.

In this article, we’ll explore how plastic machining has evolved over time, from the early days of hand-crafting to the use of computer-controlled machines and 3D printing for custom plastic fabrication. If you’re in need of a quality plastic machining company, simply get in touch with the friendly team at Johndec Engineering Plastics WA.

Early days of plastic machining

The use of plastics in manufacturing began in the early 20th century, with the advent of materials such as Bakelite, the first synthetic plastic. At that time, plastic machining was a relatively simple process that involved using hand tools to shape and cut plastic parts. Machinists used a variety of cutting tools, such as knives, saws, and chisels, to remove material and create the desired shapes.

In the 1930s, the introduction of thermoplastics, such as polystyrene and polyvinyl chloride (PVC), further expanded the use of plastics in manufacturing. However, plastic machining remained a manual process, with workers using hand tools and manual lathes to shape and cut plastic parts.

Advancements in plastics and machining technology

In the 1950s, the development of high-performance plastics, such as nylon and acrylic, marked a turning point in the plastics industry. These materials were stronger, more durable, and more heat-resistant than earlier plastics, making them ideal for use in a wide range of applications.

At the same time, advancements in machining technology were making it possible to produce more complex plastic parts with greater precision. Computer numerical control (CNC) machines were introduced, allowing machinists to program the machines to perform a wide range of cutting and shaping operations automatically. This allowed for faster, more accurate production of plastic parts, with greater consistency and reliability.

In the 1970s and 1980s, new materials such as polycarbonate and acetal were introduced, further expanding the range of plastics available for machining. These materials offered improved strength, durability, and resistance to heat and chemicals, making them ideal for use in demanding applications such as aerospace, automotive, and medical devices.

Learn even more about plastic fabrication Perth by reading our complete guide on the process.

3D printing and the future of plastic machining

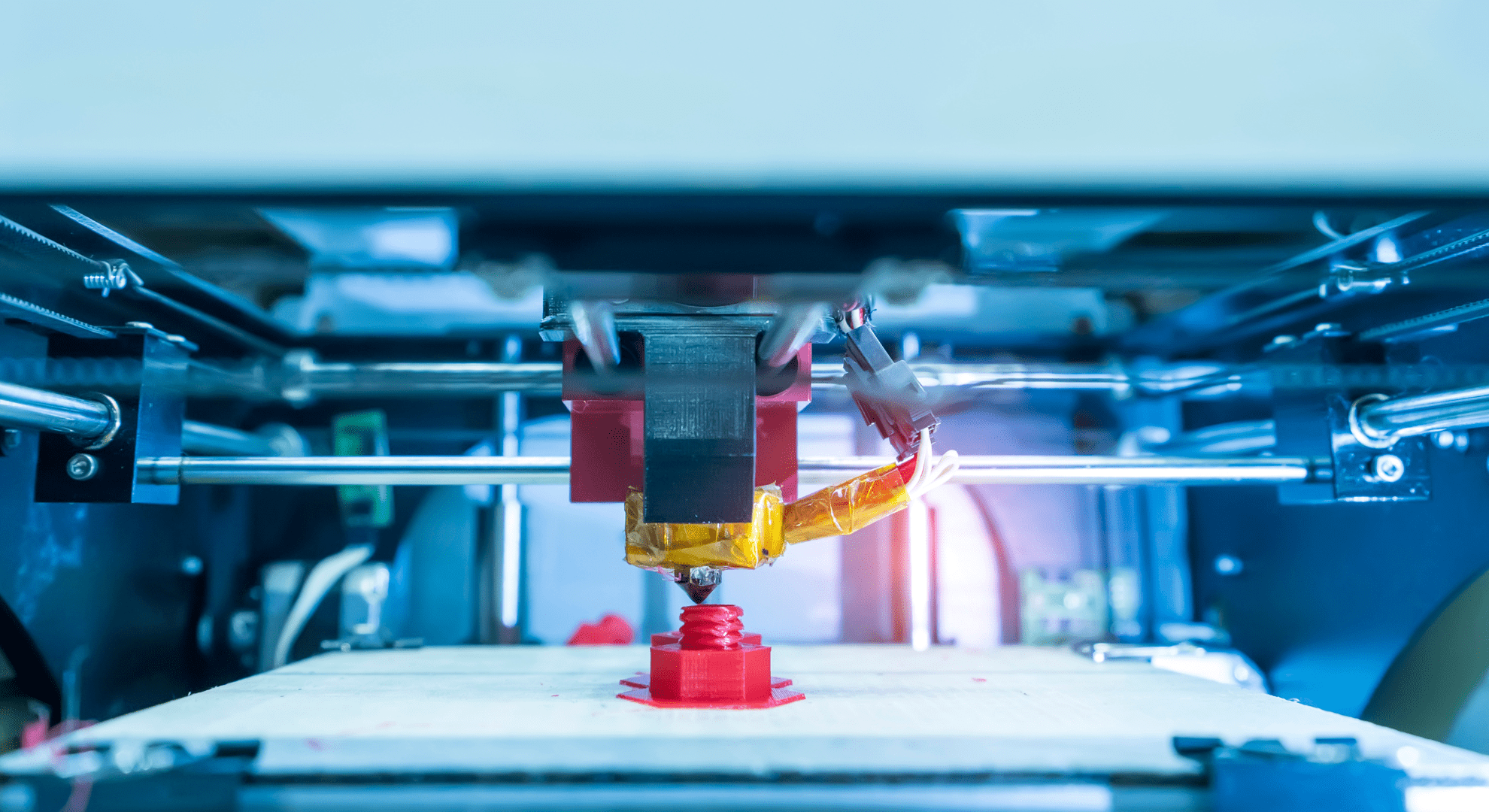

In recent years, 3D printing has emerged as a powerful new tool for creating plastic parts. 3D printing, also known as additive manufacturing, involves building up parts layer by layer using a variety of materials, including plastics. This process is particularly useful for creating complex shapes and geometries that would be difficult or impossible to achieve with traditional machining methods.

While 3D printing is not a direct replacement for traditional machining methods, it is increasingly being used in conjunction with these methods to produce plastic parts more efficiently and effectively. For example, 3D printing can be used to create a prototype of a plastic part, which can then be machined to create a finished product. This allows for faster and more efficient product development, as well as greater flexibility in design and manufacturing.

Another emerging technology that is likely to have a significant impact on plastic machining is the use of artificial intelligence and machine learning. These technologies are being used to develop new algorithms and software tools that can analyse and optimise machining processes, allowing for greater efficiency, accuracy, and quality control.

What is plastic machining used for?

This process is used to produce a wide range of plastic components that are used in various industries, including:

- Aerospace: Plastic parts are used in various applications in the aerospace industry, including aircraft interior components, electrical connectors, and ducting systems.

- Medical: Plastic components are widely used in medical devices such as surgical instruments, implantable devices, and diagnostic equipment.

Want to know more about how custom plastic components are created for medical devices? Read our article here.

- Electronics: The electronics industry uses plastic components in a range of applications, including electrical connectors, housings for electronic devices, and enclosures for circuit boards.

- Automotive: Plastic parts are used in various automotive applications, including interior and exterior trim components, engine components, and electrical connectors.

- Packaging: Plastic machining is used to produce plastic packaging components such as bottles, jars, and containers.

- Industrial: Plastic components are used in a wide range of industrial applications, including conveyor systems, gears, bearings, and rollers.

- Energy: The energy industry uses plastic components in applications such as solar panels, wind turbines, and oil and gas drilling equipment.

So, plastic machining is used in many industries to produce high-quality plastic components with tight tolerances and complex shapes. The versatility and durability of plastic materials make them an ideal choice for a wide range of applications.

What should I look for in a plastic machining company?

If you’re in need of plastic machining services, there are several factors to consider when choosing a plastic machining company. Here are some key things to look for in a good plastic machining company:

- Experience and expertise: Look for a company that has extensive experience in plastic machining and has expertise in working with a variety of plastic materials. A company with a proven track record of producing high-quality plastic components is more likely to provide reliable and consistent results.

- State-of-the-art equipment: Look for a company that uses the latest and most advanced CNC machines and other equipment for plastic machining. This will ensure that they can produce high-quality parts with precision and accuracy.

At Johndec, we update our equipment whenever it tires or becomes out of date. This allows us to deliver the best service in the industry to our customers. Learn about how you can read the signs it’s time to upgrade your plastic machining equipment.

- Design and prototyping services: A good plastic machining company should have design and prototyping services to help you develop your concept into a finished product. They should be able to work with you to optimise your design and create a prototype that meets your specifications.

- Quality control: Look for a company that has a comprehensive quality control system in place to ensure that all products meet the highest standards of quality and accuracy. This should include inspections and measurements to verify the quality of the products.

- Customer service: Look for a company that is committed to providing excellent customer service such as Johndec. They should be responsive to your needs, provide regular updates throughout the manufacturing process, and be willing to work with you to meet your specific requirements.

- Cost-effectiveness: A good plastic machining company should offer competitive pricing for their services. They should provide clear and transparent pricing structures, and be willing to work with you to find cost-effective solutions that meet your needs.

Overall, when choosing a plastic machining company, it is important to consider their experience, equipment, quality control, customer service, and pricing. By choosing a company that meets these criteria, you can be confident that you will receive high-quality plastic components that meet your needs and requirements. At Johndec Engineering Plastics WA, we see the value in delivering on our promises for each of these above factors.

What can Johndec Engineering Plastics WA do for you?

We’re a leading provider of high-quality plastic components for various industries. We offer a wide range of plastic machining services, including the design, fabrication, and installation of fume cupboards, fume exhaust fans, fume scrubbers, and other chemical exhaust systems. We’re one of the largest fume cupboard manufacturers in Australia, with expertise in producing custom plastic components for a diverse customer base.

Our plastic machining services cover a wide range of products, including fume cupboards, fume scrubbers, forensic products, electrowinning cells, auto sash controllers, ductwork, chemical-resistant sinks, custom plastics fabrication, fume exhaust fans, ductless fume hoods, and laboratory equipment. We have the expertise and experience to work with a variety of plastic materials, including high-performance engineering plastics such as PEEK, PTFE, and Ultem. Learn more about our products here.

Conclusion

Plastic machining has come a long way since its early days of manual cutting and shaping. Advancements in plastics technology, machining technology, and manufacturing practices have made it possible to produce plastic parts that are stronger, more durable, and more precise than ever before.

As we look to the future, it is clear that the process of plastic machining will continue to evolve, driven by new technologies and materials. Whether it is the use of 3D printing, artificial intelligence, or other emerging technologies, it’s likely that plastic machining will become even more efficient, cost-effective, and flexible in the years to come.

If you’re in need of high-quality plastic machining services in Western Australia, Johndec Engineering Plastics WA is an excellent choice. With over 40 years of experience in the industry, we have a proven track record of delivering top-notch plastic machining, fabrication services, and other services such as duct fittings to a diverse range of clients. So, don’t hesitate to get in touch with Johndec Engineering Plastics WA today to discuss your plastic machining needs.